Stainless Steels in Focus: Alloying, Microstructures, and Modern Tools for Innovation

The Ansys case study explores the properties and applications of stainless steels, emphasizing the role of alloying elements, microstructures, and innovative tools like Granta EduPack in enhancing engineering education. It highlights the key types of stainless steels—Ferritic, Austenitic, and Martensitic—and their unique mechanical properties.

Stainless steel, a cornerstone material in modern engineering, combines strength, durability, and corrosion resistance, making it indispensable for countless applications. Ansys’ latest industrial case study, conducted through its Granta EduPack platform, delves into the science behind stainless steel, providing valuable insights for educators and engineers alike.

Bridging Science and Engineering

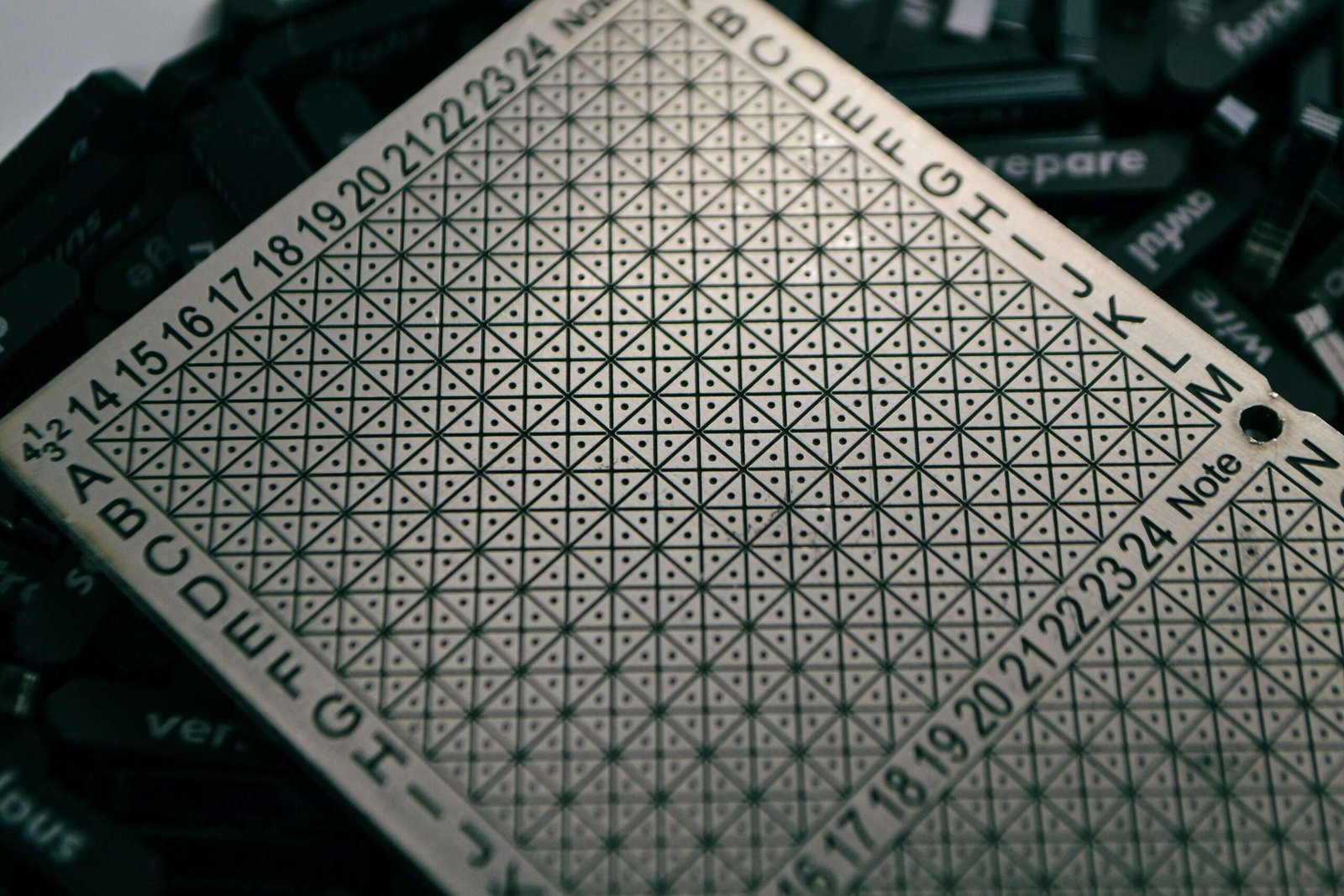

Granta EduPack has long been a go-to tool for teaching materials science and engineering. With its newly expanded features, the platform now offers enhanced visualization of binary phase diagrams and property-process profiles, enabling a deeper understanding of complex materials like stainless steel and Ni-Cr alloys.

Understanding Stainless Steel Types

The study categorizes stainless steel into three main types based on microstructure:

- Ferritic Stainless Steels: These Cr-rich alloys feature a BCC structure, offering excellent corrosion resistance and affordability.

- Austenitic Stainless Steels: With an FCC microstructure, these are the most common and versatile, often used in kitchenware and aerospace.

- Martensitic Stainless Steels: These high-carbon alloys are heat-treatable, making them ideal for bolts and screws.

Each type’s unique composition and properties are explored in detail, highlighting the role of alloying elements like chromium, nickel, and molybdenum in enhancing performance.

Innovative Tools for Education

The case study showcases how tools like the Phase Diagram Tool and MS&E data-tables can simplify the teaching of complex concepts, such as precipitation hardening. These features bridge the gap between theoretical science and practical engineering, equipping students with the knowledge to make informed material selections.

Real-World Applications

From beer barrels to aerospace components, stainless steel’s versatility is unparalleled. The study underscores its importance in high-stress, corrosive environments, demonstrating how thoughtful alloying and heat treatment can tailor properties to specific needs.

Ansys’ case study is a testament to the power of combining advanced educational tools with real-world insights, empowering engineers to push the boundaries of innovation.

Credit: Case study courtesy of Ansys Education Resources, highlighting the role of Granta EduPack in advancing materials science education.