Driving Innovation: How High-Performance Stainless Steel is Shaping the Future of the Automotive Industry

High-performance stainless steel is revolutionizing the automotive industry with applications in EVs, exhaust systems, and structural components, enhancing durability, safety, and sustainability. Its strength and corrosion resistance make it essential for advancing fuel efficiency and reducing emissions in modern vehicles.

As the automotive industry drives forward with innovations in efficiency and sustainability, stainless steel has become an essential material for its superior performance in electric vehicles (EVs), exhaust systems, and structural components. Known for its strength, corrosion resistance, and versatility, stainless steel plays a vital role in meeting the evolving demands of modern vehicles.

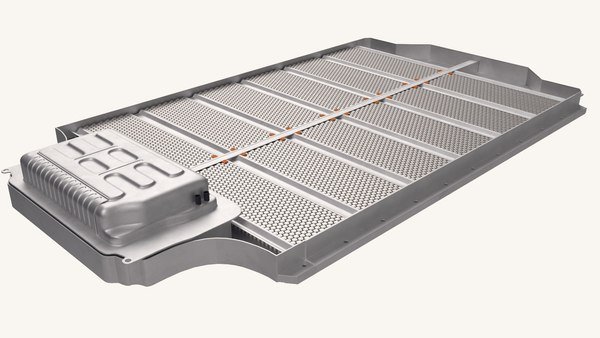

In EVs, automotive-grade stainless steel is used for lightweight yet durable battery enclosures and structural frames that withstand high temperatures and mechanical stresses. The material’s corrosion resistance ensures longevity, a critical factor as EV components must endure various environmental conditions. For example, Tesla employs high-grade stainless steel for battery enclosures in its Model S, ensuring protection and durability under various temperature and impact conditions, crucial for EV safety.

Exhaust systems also benefit significantly from stainless steel’s heat resistance and ability to withstand corrosive gasses, increasing vehicle lifespan while improving fuel efficiency by reducing the need for frequent repairs or replacements. In the pursuit of sustainable practices, high-performance stainless steel is further applied in catalytic converters and particulate filters to minimize emissions.

In chassis and structural applications, stainless steel’s strength-to-weight ratio enables safer and lighter designs, contributing to fuel economy and reduced emissions. This material also allows manufacturers to explore sleeker designs that are more aerodynamic and energy-efficient, which is pivotal in both conventional and electric vehicles. Ford uses stainless steel in specific chassis parts, balancing the vehicle’s weight while maintaining structural strength, leading to better fuel efficiency in models like the F-Series trucks.

The versatility and durability of high-performance stainless steel make it indispensable for the future of automotive innovation, aligning with industry goals for improved sustainability, safety, and efficiency.