Outokumpu Partners with Boston Metal to Advance Carbon-Free Metals Production

Outokumpu

Outokumpu, the global leader in sustainable stainless steel, signs a Memorandum of Understanding with Boston Metal to develop carbon-free metals. The US-based technology company, Boston Metal, is reshaping the global metals industry with its Molten Oxide Electrolysis (MOE) technology. Together, the two firms plan to accelerate the production of carbon-free metals needed for sectors such as defence and aerospace.

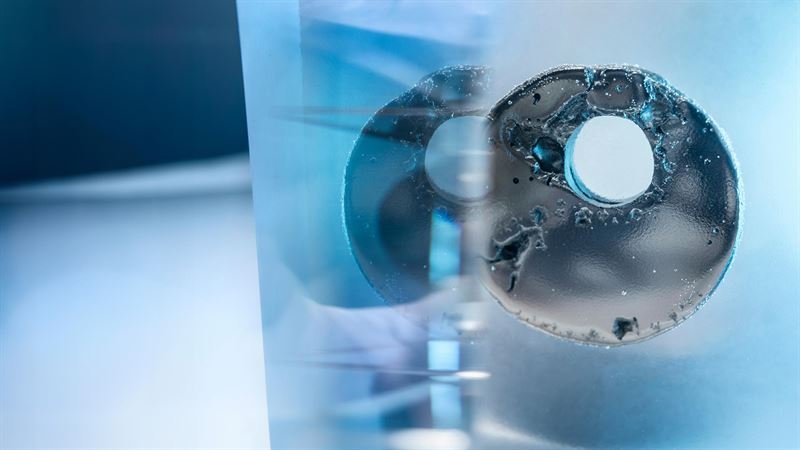

As per the agreement, the two companies will launch a joint development project. Outokumpu will supply chromium feedstock and chrome oxide from its Kemi mine in Finland. Boston Metal will test its MOE technology using this material. The project aims to improve side-stream recycling within Outokumpu’s operations and strengthen its circularity approach.

At the same time, the partnership will work to secure a reliable chromium supply chain. Outokumpu will provide material for Boston Metal’s inert anode, which is a key part of MOE technology for green steel. The companies believe this collaboration can improve efficiency, cut carbon emissions and deliver sustainable value across the metals industry.

Stefan Erdmann, Chief Technology Officer at Outokumpu, said the collaboration marks a big step. He noted that the project will push Outokumpu’s proprietary technology, revealed at its Capital Markets Day in June 2025, to new levels. He added that the deal supports the company’s EVOLVE strategy for 2026–2030.

Boston Metal is moving quickly to scale its breakthrough process. The company is commissioning its first commercial plant in Brazil. The facility will produce critical metals such as niobium and tantalum. At the same time, Boston Metal is scaling its modular MOE technology for higher-volume applications like iron and steel.

Adam Rauwerdink, Senior Vice-President of Business Development at Boston Metal, welcomed the partnership. He said the work with Outokumpu will unlock new economic opportunities across the metals industry. He also noted that the deal will deliver sustainable and profitable pathways for future production.

With this partnership, both firms aim to advance technology that reduces emissions while expanding economic opportunities.