Outokumpu Announces Breakthrough Low-CO₂ Metal Extraction Technology

Outokumpu has revealed a major leap forward in green metallurgy as it introduces a new low-CO₂ metal extraction technology. The company spent four years developing a proprietary process that breaks the long link between ore and finished metal. As a result, the team now claims a major breakthrough in the push toward cleaner metals.

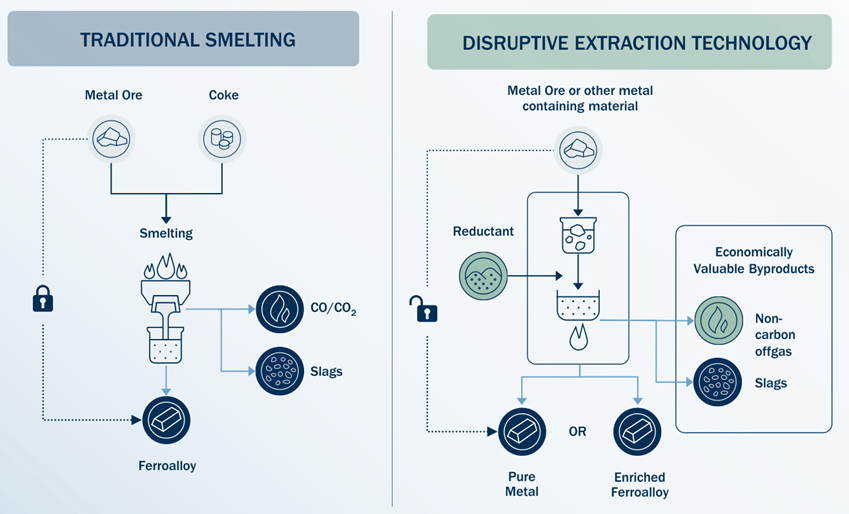

However, this new platform goes further than emissions reduction. It also improves the quality of final materials. Outokumpu designed the system to eliminate carbon-based reductants. Instead, the new method uses a flexible process that generates non-carbon off-gases. Therefore, the full chain gains lower emissions and better sustainability. The process also unlocks fresh sidestream value, and it helps the company improve cost competitiveness.

Furthermore, the shift frees metal quality from ore limitations. Outokumpu can now turn marginal or low-grade resources into high-value materials. The Kemi mine in Northern Finland currently produces ferrochrome with 53 per cent chromium. The new technology enriches this to 65 per cent and even pure chrome metal.

Industries such as aerospace, defence, energy and advanced manufacturing will gain access to higher-purity materials. They also gain a more secure supply chain.

Outokumpu started this journey in 2021 when its team began developing a carbon-neutral ferrochrome process. In 2024, the company opened a research lab near Boston in the US. The team then expanded its intellectual property portfolio, and it now prepares to scale the process further.

The company grew output from 1 g in early lab tests to 1 kg in larger trials. Next, by 2027, it plans to build a pilot plant in New Hampshire in the US. This site will scale production from 1 kg to 1 tonne per day. Outokumpu expects full industrialisation between 2029 and 2030. Later, from 2030 onwards, the company aims to unlock the full commercial value of this innovation.

This breakthrough also fits directly into Outokumpu’s EVOLVE strategy. The company wants to grow into high-value markets that demand high-purity chromium materials. These materials command stronger pricing as purity increases.

Moreover, the innovation strengthens Outokumpu’s independence. Western markets lack secure supply chains for high-purity chromium. Outokumpu now plans to fill that gap. It sees rising geopolitical risks, and it believes secure, clean raw materials will matter more than ever.

Outokumpu will now move toward offering low-carbon metals essential for stainless steel and advanced applications. The company sees strong future demand for clean, high-performance stainless steel materials. It also believes the market offers almost unlimited potential as industries seek lower emissions and safer supply chains.

The company has a long history of innovation, and now it aims to rewrite the future of metal production. The Avesta site in Sweden produced the first Duplex stainless steel. The company also invented flash smelting in the 1940s. This process later changed global copper production.