Designers have to first understand that the consumers are changing

Bhumika Sukhadia, Co-founder, OPE Innovation Lab, Mumbai discusses the sustainability of stainless steel (SS), highlighting its durability, corrosion resistance and recyclability, which make it a preferred choice for various applications.

As an accomplished product designer and architect, can you share what inspires your designs and how you integrate design thinking into your creative process?

We are a research driven Product Design studio focused on translating good quality user interaction into tangible solutions with crisp execution. Usually, it’s the context and the people who predominantly drive our designs. If I specifically talk about the design forms, a huge inspiration for me comes from a) the design history the world has seen and b) the materials and manufacturing processes involved.

What role does stainless steel play in your projects, and what are some unique properties of this material that make it a preferred choice in your designs?

It’s an inherently sustainable material and 100 per cent recyclable which makes it very relevant for us as we are shifting gears towards design for the planet. As it is corrosion resistant and durable it is used in a wide range of applications like medical and surgical equipment, furniture, commercial kitchens, automotive parts, architecture, sanitary fixtures, hardware products, cookware, etc. Very interestingly, the Tesla Cybertruck uses an ultra hard stainless steel exoskeleton. The fashion industry has also actively experimented with this material. Fashion accessories and watches made in SS are widely sold by brands in the affordable luxury segment eg. Inox Jewelry for men, Ishhaara for women are Indian brands.

What are some of the challenges you’ve encountered while working with stainless steel, and how have you overcome them through innovative design solutions?

What are some of the challenges you’ve encountered while working with stainless steel, and how have you overcome them through innovative design solutions?

When we are working on SS products that are meant to be mass produced the manufacturing processes and their constraints are already known to us and our designs are conceptualised and engineered accordingly. In such projects, we also have adequate support from our clients to prototype and test manufacturing details and finishes in their development labs. The challenges arise when we are working on custom made products or furniture pieces which are locally made using basic machines and tools with manual labour involved. The machines required for adequate forming, bending, welding SS components/ rods/ sheets are not very commonly accessible and good quality trained professionals who can work on them are rare. PVD and other chemical coatings are now available for getting a colored finish on SS but again these processes are hard to access for customised products/ smaller batches of production.

Could you highlight a few of your notable projects where stainless steel was a key component, and explain why it was chosen over other materials?

We are currently developing a range of stainless steel bathroom accessories for a sanitary ware company which is also manufacturing in India. Traditionally in India, SS has always been the most important material in our kitchens after earthenware. The relationship is long proven and we have always used it for places wherever we had active interaction with water. Many new variations of bathroom accessories in wood, plastic and ceramic have also entered the market, yet SS accessories continue to have a larger customer base for companies in India. During our User Research we studied the general bathroom sizes and the different habits of users across age groups around storage and accessibility of products within them. We identified that people prefer SS accessories in bathroom spaces because breakage of components, less durability, discolouration/ removal of colour coating, fungal growth, etc, is common for materials like wood, plastic and ceramic. Predominantly, every household had some repeated routine for washing and maintenance of bathrooms which further reinforces the choice of material. SS accessories also had a common issue of scratches and scaling on the surface after prolonged use.

Design concepts for bathroom accessories in SS developed by OPE Innovation Lab**

How do you address sustainability and environmental considerations in your work with stainless steel, and what practices do you follow to ensure eco-friendly design?

For the bathroom accessories, since it is sheet material fabrication, the material itself calls for modern and sleek design details. The designs have to be optimised for reducing any access material going into making of a single unit; as this quantity multiplies in lakhs during mass production. Metal is an expensive material, so the weight of the product is also optimised without affecting the functionality of the product. Sheet metal fabrication starts with punching/ CNC laser cutting where manufacturing experts have started using smart nesting softwares to minimise material wastage, save cost and optimise production.

Nesting component shapes for CNC laser cutting of metal sheet to minimize material wastage *

What future trends do you foresee in the use of stainless steel within the fields of product design and architecture, and how are you preparing to embrace these trends?

Earlier SS was used for commercial kitchens at a large scale due to its durability, hygiene and ease of cleaning. From our research experience with Indian household kitchens, we see a great scope in developing a kitchen that is fully made in SS. With advanced manufacturing processes and material finishing, functional yet aesthetic residential kitchens can now be developed. The recent health crisis has alerted people that the future mass crisis would involve biological and chemical means to cause harm. SS is inert to biological growth, can be easily disinfected and remains intact during fire or flood. Such robustness in a material is a rare find and this shall find its due respect in the coming years. We are very proud to announce through this medium that we will soon be launching a one-of-its-kind kitchen and bath lab for Indian households, which will be working on making these spaces functional, modern and most of all designed for hygiene consciousness. SS and products made of it shall be one of the dominating explorations we plan to pursue under this lab.

What advice would you give to aspiring designers and architects who are interested in working with stainless steel and trying to identify unique requirements for which products can be designed using this material?

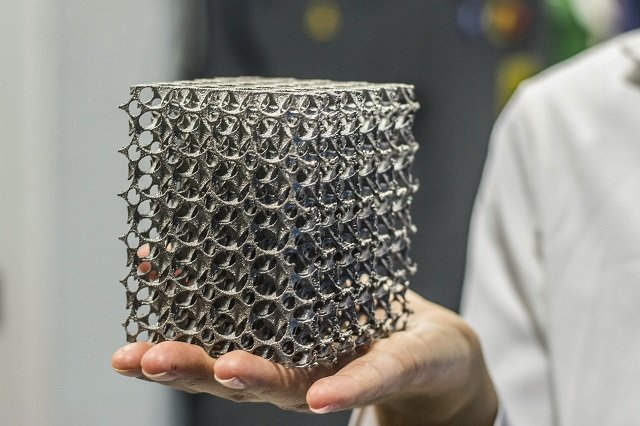

Designers have to first understand that the consumers are changing. While for the last few years everything was moving towards “fast fashion”. The world now understands that we need sustainable alternatives especially for things which we need on a regular basis. Until now, SS was a very efficient material for mass production. Mass production typically led to boring designs which people refrained from using. We have now come to a time where technologies like laser cutting and etching, 3D printing, small batch manufacturing and distributed manufacturing can help us design products which can do mass customisation. If we are able to collaborate with industry experts and optimise the journey from a sketch to a shelf, we can delight the customers with a variety of designs, fulfill their specific needs and provide this environmentally conscious material to them.

a stainless steel lattice, printed with a Selective Laser Melting printer

a stainless steel lattice, printed with a Selective Laser Melting printer