Innovative stainless steel grade: A timely alternative to cast 6Mo alloys

The N’GENIUS Series offers superior strength and corrosion resistance, outclassing traditional 6Mo alloys in extreme environments. Philip Roscoe of N’GENIUS Materials Technology explains this in further detail.

High alloyed austenitic stainless steels have played an important role since their market introduction in the early 1980s. Initially developed for seawater piping applications, ‘superaustenitic’ grades – alloys with a pitting resistance equivalent number (PREN) greater than 40 – have been widely utilised in sectors including oil and gas, pulp and paper, chemical and petrochemical and the defence industry over many decades.

Among this classification of alloys is a group of materials known as the ‘6Mo’ grades, aptly named for possessing a minimum 6 per cent molybdenum. Two of these well-known 6Mo grades – S31254 and N08367 – were first introduced as wrought materials for seawater and process piping before being used for castings, which were required for pumps and valves. Both alloys are still commonly specified in wrought and cast form.

Challenges with 6Mo grades in modern applications

As wrought and cast stainless steels involve entirely different manufacturing processes, the materials produced can often harbour different mechanical properties. Cast alloys can possess lower strength and different corrosion resistance properties compared to the wrought versions, even with the same or a very similar chemical composition.

Both the minimum yield and tensile strength of cast 6Mo alloys are lower than in the respective wrought versions, significantly impacting the suitability of these grades for use in severe conditions such as high-pressure service.

These 6Mo grades are also notoriously difficult to cast in thick sections and are prone to issues such as hot cracking, macro-segregation, micro-segregation, secondary-phase precipitation and grain growth during solution heat treatment.

Furthermore, the industry that 6Mo alloys were traditionally utilised in – oil and gas – now poses significant challenges to these materials. Extreme environments including sour gas developments often contain high levels of CO2, H2S and chlorides, requiring piping systems to have a superior corrosion resistance, which is beyond the normal range of the 6Mo grades.

As a result, the demand for improved high-performance stainless steels to help overcome these obstacles is ever increasing and a UK-based manufacturer believes it has found the solution.

British steel foundry Furniss & White has become the first company in the world to make its high integrity castings in grades from the innovative N’GENIUS Series of high strength austenitic stainless steels. The Sheffield firm, which serves the valve, pump, filter and engineering industries with castings from approximately 0.5kg to 2,600kg finished weight in a range of materials including carbon and low alloy steels, stainless steels and nickel alloys, is now manufacturing its products in various N’GENIUS grades under license.

Sam Scholes, Managing Director, Furniss & White, said, “For more than 44 years we have built a strong reputation as a high-quality British manufacturer of high integrity castings made in our modern foundry in the UK.

Now, as an approved licensed N’GENIUS manufacturer, we are writing an exciting new chapter in our history and to be the first foundry in the world to have this capability makes us extremely proud.

We expect these game-changing N’GENIUS materials will be extremely popular with our existing customers and help open up new opportunities in other markets and industries.”

The N’GENIUS Series, which can be manufactured in both wrought and cast product forms, possesses all the typical benefits of austenitic stainless steels including excellent ductility and toughness at ambient, sub-zero and cryogenic temperatures. But with far superior strength and corrosion resistance.

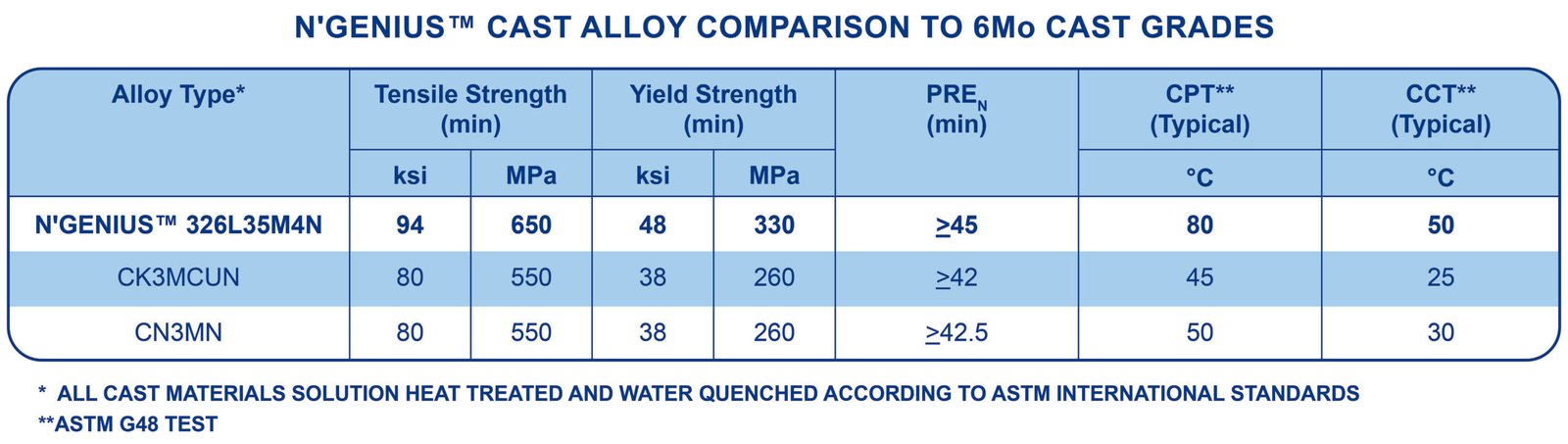

One of the N’GENIUS Series grades which is currently being utilised to manufacture castings at Furniss & White is proving to be an ideal alternative to cast 6Mo alloys. Containing a lower level of molybdenum and higher nitrogen than 6Mo, the chemical composition of N’GENIUS 326L35M4N has been carefully designed to optimise castability and performance. A comparison of the mechanical strength properties, PREN, critical pitting temperature (CPT) and critical crevice temperature (CCT) found in N’GENIUS 326L35M4N and cast 6Mo type alloys CK3MCuN and CN3MN is shown in the Table.

Weight savings and increased safety

The improved mechanical properties of N’GENIUS 326L35M4N will also allow some cast components to be designed with a reduced wall thickness compared to 6Mo alloys, providing the opportunity for significant weight savings on piping systems. Components in which wall thickness cannot be reduced can simply be designed with an increased safety factor.

Meanwhile, its improved corrosion resistance will also help improve safety, reduce maintenance costs and provide an even longer service life.

The 6Mo grades have become popular materials over many decades and will continue to be well utilised across various industries. But there is an increasing number of applications where pressures, temperatures and corrosive conditions have simply become too severe for 6Mo alloys. Superior, higher-performance austenitic stainless steels are required and the availability of N’GENIUS 326L35M4N is well timed, particularly for castings.

The N’GENIUS Series, which is patented protected in 30 countries globally, is a complete family of grades which provide an extensive choice of high strength austenitic stainless steels. Suitable for all products, all service conditions and even the harshest of process media environments, N’GENIUS is the total system material.

Captions:

- Pouring N’GENIUS 326L35M4N into cast blocks for testing at Furniss & White (Foundries) Ltd

- Table: Cast N’GENIUS 326L35M4N has superior mechanical strength and corrosion resistance compared to cast 6Mo grades

- A butterfly valve body cast in N’GENIUS 326L35M4N post fettling